|

More space for innovative paper folding solutions

GUK expands manufacturing plant by 2,000 sqm.

An extraordinary groundbreaking ceremony took place at the folding machine specialist GUK in Wellendingen during the Corona epidemic. Last week, this officially marked the start of construction of the new production hall. Times like these require extraordinary measures. And since we feel obliged to implement the safety precautions of the Federal Government, we have decided to dispense with meeting all parties involved in the project. I hope they won't hold this against us, reports Sebastian Faulhaber, who is responsible for corporate development at GUK.

Extraordinary groundbreaking ceremony due to Corona crisis.

The spacious, bright assembly hall gives the company GUK more space to further expand the strongly expanding business with paper folding machines for the pharmaceutical sector. On the approximately 2,000 sqm, mainly larger systems are to be built and further developed, which are often approved by the customers directly at the factory. In this way we are not only creating new assembly capacity and space for new applications, but also a representative environment for our customers and a transparent insight into our production, explains Faulhaber.

The planning for the new building was carried out by the architectural office Weber from Gosheim, with whom GUK already realized the last expansions in 2003-2006. The company Gebrüder Stumpp, together with the company Graf Tief- und Straßenbau, will take care of the earthworks, the concrete and masonry work. In early summer the company Stahlbau Haller from Schwenningen will follow, which is responsible for the facade. The new hall was designed with special attention to energy efficiency aspects and will feature an innovative ventilation system with high efficiency, energy-saving lighting and renewable Energy generation.

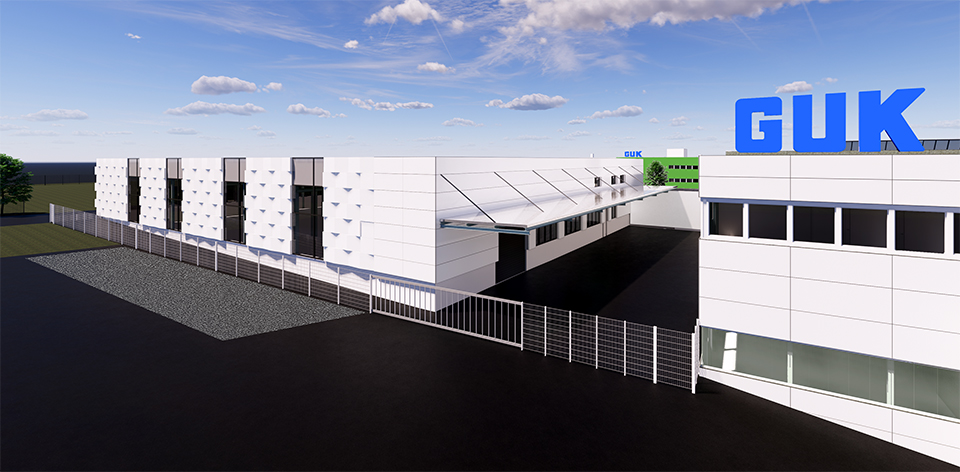

New building visualization from the Bahnhofstraße.

Special attention is paid to the integration of the new building into the existing facility, the facade and thus the face of the company. In cooperation with 3A Composites (formerly Alusingen) a unique facade was developed. The facade cladding design is based on paper folding. From the existing building, the white and smooth facade, which is based on paper sheets, is transferred to the new building. The facade panels then continue to unfold as the building progresses. This design is to represent the characteristic zig-zag folding of the products, which are produced on GUK machines. Room-high glass elements interrupt like paper rollers transporting the paper and create brightness inside.

Friedrich Faulhaber, Managing Director, praised the good cooperation with all project participants and hopes that despite the difficulties caused by the Corona crisis the construction will be carried out as planned and that the new building can perhaps be used as early as autumn this year. |

|